BITUTHENE® 3000 and BITUTHENE® Low Temperature - Above Grade

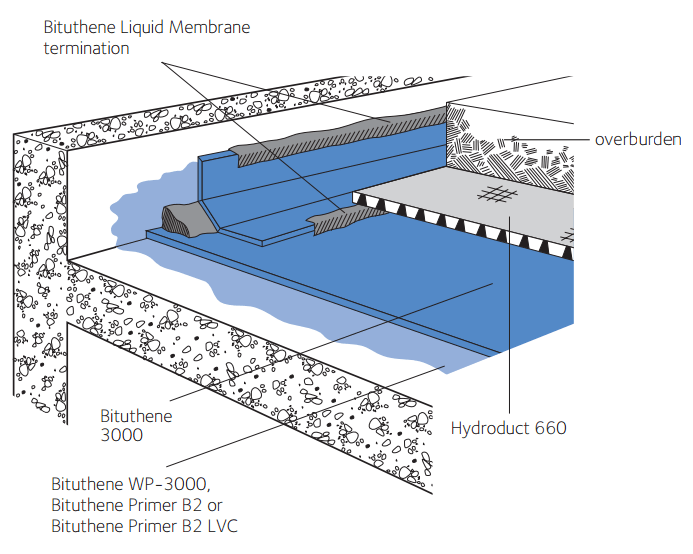

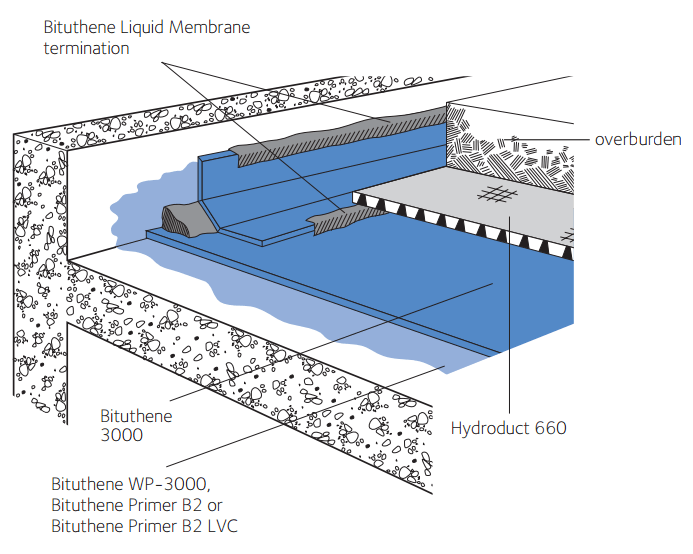

Self-adhesive, rubberized asphalt/polyethylene waterproofing membranes for plaza and parking decks

Ventajas

- Waterproof—high hydrostatic head resistance

- Cross laminated film—provides dimensional stability, high tear strength, puncture and impact resistance

- Cold applied—no flame hazard; self-adhesive overlaps ensure continuity

- Flexible—accommodates minor settlement and shrinkage movement

- Controlled thickness—factory made sheet ensures constant, non-variable site application

- Wide application window—

- Bituthene Low Temperature surface and ambient temperatures between 25 °F (-4 °C) and 60 °F (16 °C)

- Bituthene 3000 surface and ambient temperatures at 40 °F (5 °C) or above

- New or rehab construction—use with Bituthene DECK PREP® as a leveling agent and non-structural repair material

- RIPCORD®—this split release on demand feature allows the splitting of the release paper into two pieces for ease of installation in detailed areas

Uso

Bituthene is ideal for waterproofing concrete decks where in-service temperatures will not exceed 130 °F (54 °C). It can be applied to split slab construction, such as in plaza areas and parking decks. Interior uses may include mechanical rooms, laboratories, kitchens and bathrooms. (For below grade applications, see Below Grade Waterproofing Bituthene 3000 and Bituthene Low Temperature.)

Bituthene is 1⁄16 in. (1.5 mm) thick, 3 f (0.9 m) wide and 66.7 f (20 m) long and is supplied in rolls. It is unrolled sticky side down onto concrete slabs primed with Bituthene Primer WP-3000, Bituthene Primer B2 or Bituthene Primer B2 LVC. Continuity is achieved by overlapping a minimum 2 in. (50 mm) and firmly rolling the joint.

Bituthene is extremely flexible. It is capable of bridging shrinkage cracks in the concrete and will accommodate minor diferential movement throughout the service life of the structure.

Procedimientos de aplicación

Información de seguridad, almacenamiento y manipulación

Bituthene products must be handled properly. Vapors from solventbased primers and mastic are harmful and flammable. For these products, the best available information on safe handling, storage, personal protection, health and environmental considerations has been gathered. SDS (Safety Data Sheets) are available at gcpat.com and users should acquaint themselves with this information. Carefully read detailed precaution statements on product labels and the SDS before use.

Preparación de la superficie

Surfaces should be structurally sound and free of voids, spalled areas, loose aggregate and sharp protrusions. Remove contaminants such as grease, oil and wax from exposed surfaces. Remove dust, dirt, loose stone and debris. Concrete must be properly cured (minimum 7 days for normal structural concrete and 14 days for lightweight structural concrete).

If time is critical, Bituthene Primer B2 or Bituthene Primer B2 LVC may be used to allow priming and installation of membrane on damp surfaces or green concrete. Priming may begin in this case as soon as the concrete will maintain structural integrity. Use form release agents which will not transfer to the concrete. Remove forms as soon as possible from below horizontal slabs to prevent entrapment of excess moisture. Excess moisture may lead to blistering of the membrane. Cure concrete with clear, resin-based curing compounds which do not contain oil, wax or pigment. See Technical Letter 5 for more information. Except with Bituthene Primer B2 or Bituthene Primer B2 LVC, allow concrete to thoroughly dry following rain. Do not apply any products to frozen concrete.

Repair defects such as spalled or poorly consolidated areas. Remove sharp protrusions and form match lines. For rough or uneven deck surfaces use Bituthene Deck Prep as a repair and leveling agent. See Above Grade Waterproofing Bituthene Deck Prep product information sheet for details. On masonry surfaces, apply a parge coat to rough concrete block and brick walls or trowel cut mortar joints flush to the face of the concrete blocks.

Temperature

- Apply Bituthene 3000 Membrane only in dry weather and at air and surface temperatures of 40 °F (5 °C) and above.

- Apply Bituthene Low Temperature Membrane only in dry weather and when air and surface temperatures are between 25°F (-4 °C) and 60 °F (16 °C).

- Apply Bituthene Primer WP-3000 in dry weather above 40 °F (5 °C).

- Apply Bituthene Primer B2 or Bituthene Primer B2 LVC in dry weather above 25 °F (-4 °C). (See separate product information sheet.)

Priming

- Apply Bituthene Primer WP-3000 by spray or roller at a coverage rate of 500–600 f2/gal (12–15 m2/L). Allow to dry one hour or until concrete returns to original color.

- Apply Bituthene Primer B2 by a lamb’s wool roller at a coverage rate of 250–350 f2/gal (6–8 m2/L). Allow primer to dry one hour or until tack-free.

- Apply Bituthene Primer B2 LVC by a lamb’s wool roller at a coverage rate of 325–425 f2/gal (7.5–10.0 m2/L). Allow primer to dry one hour or until tack-free.

- Dry time may be longer in cold temperatures. Reprime areas if contaminated by dust. If the work area is dusty, apply membrane as soon as the primer is dry.

- Do not apply any primer onto Bituthene membrane.

Detalles sobre los vértices

El tratamiento de los vértices varía según su ubicación. Para obtener información detallada sobre BITUTHENE® Liquid Membrane, consulte la hoja de información del producto.

- En plaza decks a los vértices interiores de la pared:

- Option 1: Apply membrane on wall and deck to within 1 in. (25 mm) of corner. Treat the inside corner by installing a ¾ in. (20 mm) fillet of Bituthene Liquid Membrane. Extend Bituthene Liquid Membrane at least 2½ in. (65 mm) onto deck membrane, and 2½ in. in. (65 mm) onto wall membrane. Terminate top of wall flashing with Bituthene Mastic, Bituthene Liquid Membrane or termination bar.

- Option 2: Apply membrane on deck to within 1 in. (25 mm) of corner. Treat the inside corner by installing a ¾ in. (20 mm) fillet of Bituthene Liquid Membrane. Extend Bituthene Liquid Membrane at least 2½ in. (65 mm) onto wall.

- Opción 3: aplique la membrana sobre la cubierta a 1 in (25 mm) del vértice. Trate el interior del vértice mediante la instalación de una curva de ¾ in (20 mm) de BITUTHENE® Liquid Membrane. Aplique una lámina de flashing de la membrana en la pared, sobre la curva y 6 in (150 mm) sobre la membrana de la cubierta. Aplique 1 in (25 mm) de alisado con BITUTHENE® Mastic o BITUTHENE® Liquid Membrane sobre todas las terminaciones y uniones a 12 in (300 mm) del vértice. Termine la parte superior de los flashings de pared con masilla, BITUTHENE® Liquid Membrane o con una barra de terminación.

- In planters, reflecting pools and fountains, apply membrane on wall and deck to within 1 in. (25 mm) of corner. Treat the inside corner by installing a ¾ in. (20 mm) fillet of Bituthene Liquid Membrane. Extend Bituthene Liquid Membrane at least 2 ½ in. (65 mm) onto deck membrane, and 2½in. (65 mm) onto wall membrane. Terminate top of wall membrane with Bituthene Liquid Membrane or termination bar.

- Wall to wall inside corner, apply 12 in. (300 mm) sheet membrane strip centered on corner. Press membrane tightly into corner to ensure full contact. Cover the treated corner with a full sheet of membrane to ensure 2-ply coverage.

- En los vértices exteriores, aplique 12 in (300 mm) de tira de membrana en el centro del vértice. Cubra el vértice tratado con una lámina completa de membrana para asegurar la cobertura de 2 capas.

Aislamiento

Always apply Bituthene membrane directly to primed or conditioned structural substrates.

Insulation, if used, must be applied over the membrane. Do not apply Bituthene membranes over lightweight insulating concrete.

Approvals

- City of Los Angeles Research Report RR 24386

- Miami-Dade County Code Report NOA 04-0114.03

- U.S. Department of Housing and Urban Development (HUD) HUD Materials Release 628E

- Bituthene 3000 and Low Temperature Membranes carry a Underwriters’ Laboratory Class A Fire Rating (Building Materials Directory, File #R7910) when used in either of the following constructions:

- Limited to noncombustible decks at inclines not exceeding ¼ in. (6 mm) to the horizontal 1 f (0.3 m). One layer of Bituthene waterproofing membrane, followed by one layer of ⅛ in. (3 mm) protection board, encased in 2 in. (50 mm) minimum concrete monolithic pour.

- Limited to noncombustible decks at inclines not exceeding ¼ in. (6 mm) to the horizontal 1 f (0.3 m). One layer of Bituthene waterproofing membrane, followed by one layer of DOW Styrofoam PD Insulation Board [2 in. (50 mm) thick]. This is covered with one layer of 2 f x 2 f x 2 in. (0.6 m x 0.6 m x 50 mm) of concrete paver topping.

Garantía

Five year material warranties covering Bituthene and HYDRODUCT® products are available upon request. Contact your GCP sales representative for details.

Servicios técnicos

El soporte es proporcionado por representantes de GCP y personal de servicio técnico de tiempo completo y con formación técnica, que además están respaldados por un personal central de investigación y desarrollo.

Suministro

| Product Property | Total |

|---|---|

| Bituthene 3000 or Bituthene Low Temperature | 3 ft x 66.7 ft roll (200 ft2) [0.9 m x 20 m (18.6 m2)] |

| Roll weight | 83 lbs (38 kg) gross |

| Paletización | 25 rolls per pallet |

| Almacenamiento | Store upright in dry conditions below 95°F (+35°C). |

| Ancillary Products | Total |

|---|---|

| Bituthene WP-3000 | 5 gal (18.9 L) pail/24 pails per pallet |

| Bituthene Primer B2 | 5 gal (18.9 L) pail/48 pails per pallet |

| Bituthene Primer B2 LVC | 5 gal (18.9 L) pail/48 pails per pallet |

| BITUTHENE® Liquid Membrane | 1.5 gal (5.7 L) pail/125 pails per pallet or 4 gal (15.1 L) pail/48 pails per pallet |

| PREPRUFE® Detail Tape | 2 in. x 50 ft (50 mm x15 m) roll/16 rolls per carton |

| Bituthene Mastic | 4 gal (15.1 L) pail/24 pails per pallet |

| Complementary Material | Total |

|---|---|

| Hydroduct | See separate data sheets |

Equipment by others: Soft broom, utility knife, brush or roller for priming

Propiedades físicas

| Propiedad | Typical Value | Método de prueba |

|---|---|---|

| Color | Dark gray-black | |

| Espesor | 1⁄16 in. (1.5 mm) nominal | ASTM D3767—method A |

| Flexibility, 180° bend over 1 in. (25 mm) mandrel at -25°F (-32°C) |

Unaffected | ASTM D1970 |

| Tensile strength, membrane, die C | 325 lbs/in.2 (2240 kPa) minimum | ASTM D412 modified1 |

| Tensile strength, film | 5,000 lbs/in.2 (34.5 MPa) minimum | ASTM D882 modified1 |

| Elongation, ultimate failure of rubberized asphalt | 300% minimum | ASTM D412 modified1 |

| Crack cycling at -25°F (-32°C), 100 cycles | Unaffected | ASTM C836 |

| Lap adhesion at minimum application temperature | Bituthene 3000: 4 lbs/in. (700 N/m) Bituthene Low Temp: 5 lbs/in. (880 N/m) |

ASTM D1876 modified2 |

| Peel strength | 9 lbs/in. (1576 N/m) | ASTM D903 modified3 |

| Puncture resistance, membrane | 50 lbs (222 N) minimum | ASTM E154 |

| Resistance to hydrostatic head | 200 ft (60 m) of water | ASTM D5385 |

| Permeance | 0.05 perms (2.9 ng/m2sPa) maximum | ASTM E96, section 12—water method |

| Water absorption | 0.1% maximum | ASTM D570 |

Footnotes:

1. The test is run at a rate of 2 in. (50 mm) per minute.

2. The test is conducted 15 minutes after the lap is formed and run at a rate of 2 in. (50 mm) per minute at 40°F (5°C).

3. The 180° peel strength is run at a rate of 12 in. (300 mm) per minute.

Expansion Joints in Concrete Construction

Bituthene membrane is not an expansion joint filler or sealant, but may be used as an expansion joint cover only in limited, special situations, as shown in Figures 1 and 2.

To adequately waterproof an expansion joint requires the use of materials specifically designed to do that job. Bituthene waterproofing systems can, in most cases, be tied into expansion joint waterproofing and/or covering systems to provide full waterproofing protection on a project.

Project designers and/or contractors should consult with expansion joint sealant and covering manufacturers for design and installation details. A partial listing of manufacturers is included in Technical Letter 11. Also, Section 05800 of Sweets, Expansion Control, and Section 07920, Sealant and Caulking, provide information on manufacturers and design possibilities.

Designers should consider using gutters under critical expansion joints to provide a second line of defense against seal failure.

Use of Bituthene Membrane as an Expansion Joint Cover

Figures 1 and 2 illustrate the use of Bituthene membrane as an expansion joint cover.

gcpat.mx | Servicio al cliente de América Latina: +55-11-97320-4104

Esperamos que esta información le resulte útil. Se basa en datos y conocimientos considerados verdaderos y precisos y se ofrecen para consideración, investigación y verificación por parte del usuario, pero no garantizamos que se obtengan resultados. Lea todas las declaraciones, recomendaciones y sugerencias junto con nuestras condiciones de venta que aplican a todos los bienes que suministramos. Ninguna declaración, recomendación o sugerencia está destinada para algún uso que pudiera violar una patente, derecho de propiedad intelectual o derecho de terceros.

Bituthene, Deck Prep, Ripcord, Hydroduct y Preprufe son marcas registradas de GCP Applied Technologies Inc. que pueden estar registradas en Estados Unidos y/o en otros países. Esta lista de marcas se ha compilado utilizando la información publicada disponible a partir de la fecha de publicación y puede no reflejar con exactitud la propiedad o el estado actual de la marca.

© Copyright 2016 GCP Applied Technologies Inc. Todos los derechos reservados.

GCP Applied Technologies Inc., 62 Whittemore Avenue, Cambridge, MA 02140 EE. UU.

En Canada, 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

Este documento solo está vigente a partir de la última fecha de actualización que se indica a continuación y es válido solo para su uso en México. Es importante que siempre se refiera a la información disponible actualmente en la siguiente URL para proporcionar la información del producto más actualizada al momento de su uso. También se encuentra disponible en www.gcpat.mx literatura adicional como Manuales del contratista, boletines técnicos, planos detallados y recomendaciones detalladas y otros documentos relevantes. No se debe confiar en la información que se encuentra en otros sitios web, ya que pueden no estar actualizados o ser aplicables a las condiciones en su ubicación y no aceptamos ninguna responsabilidad por su contenido. Si hay algún conflicto o si necesita más información, comuníquese con el Servicio al cliente de GCP.

Last Updated: 2023-07-07

https://gcpat.mx/es-la/solutions/products/bituthene-post-applied-waterproofing/bituthene-3000-and-bituthene-low-0